What is Orbital Welding

Orbital welding is Automatic Tungsten inert gas welding. It eliminates chances of manual errors in welding. It produces identical welds for hundred of times hence accuracy in welding.

ORBITAL WELDING TECHNIQUE

Orbital Fusion Tube Welding is typically done as a single-pass fusion butt weld. The weld sequence starts with a timed prep urge, during which the enclosed weld head fills with inert gas, usually argon. An arc is struck between the tungsten electrode and the weld joint, and arc rotation begins after a timed delay during which the weld puddle is formed and just penetrates the tube.

The orbital weld bead is smoother, providing a higher-quality weld that can be repeated consistently.

Orbital welds in high-purity piping systems now number in the millions.

Orbital welding was first used in the 1960's when the aerospace industry recognized the need for a superior

joining technique for aerospace hydraulic lines. Orbital welding became practical for many industries in the

early 1980's when combination power supply / control systems were developed that operated from 110-

220 V AC and were physically small enough to be carried from place to place on a construction site for

multiple in-place welds. Modern day orbital welding systems offer Micro processor control where welding

parameters for a variety of applications can be stored in memory and called up when needed for a specific

application. The skills of a certified welder are thus built into the welding system, producing enormous

numbers of identical welds and leaving significantly less room for error or defects.

ORBITAL WELDING EQUIPMENT

In the orbital welding process, tubes / pipes are clamped in place and an orbital weld head rotates an electrode and electric arc around the weld joint to make the required weld. An orbital welding system consists of a power supply and an orbital weld head.

POWER SUPPLY

IThe power supply / control system supplies and controls the welding parameters according to the specific weld program created or recalled from memory. The power supply provides the control parameters, the arc welding current, the power to drive the motor in the weld head and switches the shield gas on / off as necessary.

WELD HEAD

Orbital weld heads are normally of the enclosed type and provide an inert atmosphere chamber that surrounds the weld joint. Standard enclosed orbital weld heads are practical in welding tube sizes from 1/2 inch (12mm) to 6 inches (152mm) with wall thickness' of up to 0.154 inches (3.9mm) Larger diameters and wall thickness' can be accommodated with open style weld heads.

THE PHYSICS OF GTAW PROCESS

OThe orbital welding process uses the Gas Tungsten Arc Welding process (GTAW) as the source of the electric arc that melts the base material and forms the weld. In the GTAW process (also referred to as the Tungsten Inert Gas process - TIG) an electric arc is established between a Tungsten electrode and the part to be welded. To start the arc, an RF or high voltage signal (usually 3.5 to 7 KV) is used to break down (ionize) the insulating properties of the shield gas and make it electrically conductive in order to pass through a tiny amount of current. A capacitor dumps current into this electrical path, which reduces thearc voltage to a level where the power supply can then supply current for the arc. The power supply responds to the demand and provides weld current to keep the arc established. The metal to be welded is melted by the intense heat of the arc and fuses together.

INDUSTRIAL APPLICATION OF ORBITAL WELDING

May be used in applications where access space restrictions limit the physical size of the welding device. Weld heads may be used in rows of boiler tubing where it would be difficult for a manual welder to use a welding torch or view the weld joint..

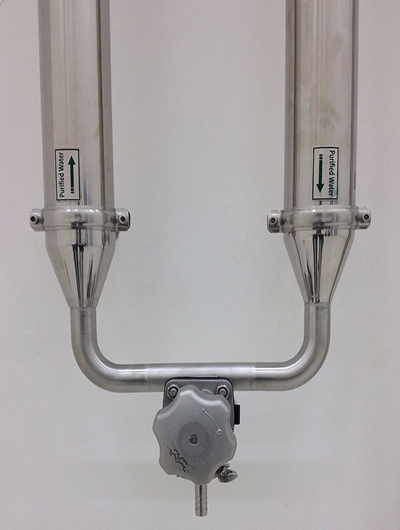

PHARMACEUTICAL INDUSTRY

Pharmaceutical process lines and piping systems deliver high quality water to their processes. This requires high quality welds to ensure a source of water from the tubes that is uncontaminated by bacteria, rust or other contaminant. Orbital welding ensures full penetration welds with no overheating occurring that could undermine the corrosion resistance of the final weld zone. Type 316L stainless steel tubing is used extensively for critical piping systems in Pharmaceuticals and Food industries in which maintaining the cleanliness of high-purity liquids and gases passing through these systems is fundamental to successful product yield.

FOOD, DAIRY & BEVERAGE INDUSTRIES

The food, dairy and beverage industries require consistent full penetration welds on all weld joints. Most of these tubing / piping systems have schedules for cleaning and sterilization in place. For maximum piping system efficiency the tubing must be as smooth as possible. Any pit, crevice, crack or incomplete weld joint can form a place for the fluid inside the tubing to be trapped and form a bacteria harbor. Stainless steel is used by the dairy, food, and other industries because it can be polished to a smooth, hard, relatively inert surface finish that can be maintained in a sanitary condition without degradation by corrosion.

REASON FOR USING ORBITAL WELDING EQUIPMENT

There are many reasons for using orbital welding equipment. The ability to make high quality, consistent welds repeatedly at a speed close to the maximum weld speed offer many benefits to the user:

Productivity: An orbital welding system will drastically outperform manual welders.

Quality: The quality of a weld created by an orbital welding system with the correct weld program will be superior to that of manual welding. In applications such as pharmaceutical or semiconductor tube welding, orbital welding is the only means to reach the weld quality requirements.

Consistency: Once a weld program has been established an orbital welding system can repeatedly perform the same weld hundreds of times, eliminating the normal variability, inconsistencies, errors and defects of manual welding.

Orbital welding: May be used in applications where a tube or pipe to be welded cannot be rotated or where rotation of the part is not practical.

SOME DROP POINTS MADE BY TEAM TECHNOMECH: